Why Stainless Steel Tube Fittings Deliver Long-Term Value

Why Stainless Steel Tube Fittings Deliver Long-Term Value

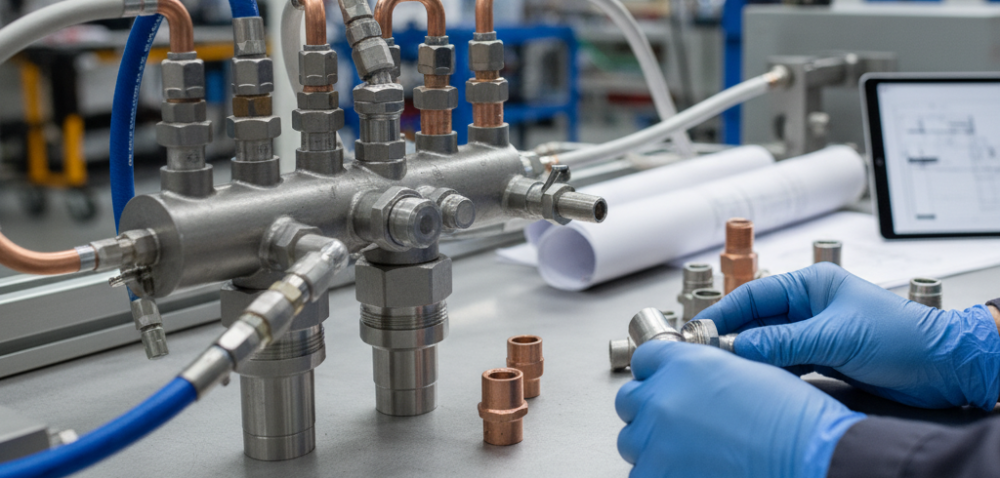

Stainless steel tube fittings are the backbone of reliable piping systems. Compared with standard carbon steel or brass, stainless steel offers superior resistance, strength, and value over time.

1. Corrosion Resistance

Stainless steel fittings, including SS tube fittings, stainless steel pipe connectors, and stainless tubing fittings, are highly resistant to rust, acids, and chemicals. This makes them ideal for industries like pharmaceuticals, petrochemicals, and marine.

2. Strength & Durability

Unlike ordinary materials, stainless steel maintains integrity under high pressure tube fittings and extreme temperatures. From tube elbows to pipe ferrules, stainless steel ensures leak-proof, long-lasting performance.

3. Cost vs. Value

While initial costs may be higher than standard fittings, stainless steel delivers long-term value by reducing replacement frequency, downtime, and maintenance costs.

4. Applications

- Chemical plants

- Food and beverage systems

- Oil & gas pipelines

- Industrial machinery

5. Why Excel Flow Control?

We offer a complete range of stainless steel pipe and fittings, SS pipe connectors, stainless steel tube fittings, and tube weld fittings. Our catalog ensures the right part for every application.

Conclusion: Investing in stainless steel fittings ensures performance and safety. At Excel Flow Control, we deliver only the highest quality.

Suggested Image Prompt:

“Shiny stainless steel tube fittings and pipe clamps arranged neatly on a clean industrial workbench, reflective surfaces, modern factory lighting.”

Related Blogs

- May 10, 2025

- By Owner

Essential Guide to Tube Fittings for Fluid Control

Explore tube fittings, their types, applications, and tips for installation and maintenance to ensure leak-free connections in fluid systems.

- September 29, 2025

- By Owner

Ultimate Guide to Tube Fittings: INCH and METRIC OD Tubes Explained

Tube fittings are a critical component in fluid and gas transfer systems across industries like oil & gas, chemical processing, power generation, instrumentation, and more. Their purpose is to connect different parts of a piping or tubing system securely and reliably without leaks. Whether you're working with hydraulic lines, pneumatic systems, or instrumentation setups, selecting the right tube fitting is essential to ensure safety, performance, and longevity.

- May 10, 2025

- By Owner

Precision Engineered Needle Valves for Every Industrial Need | Excel Flow Control

Excel Flow Control offers precision-engineered needle valves designed for high-pressure and high-temperature applications. Available in various configurations, our valves ensure leak-free performance and accurate flow control across critical industrial processes.

- September 29, 2025

- By Owner

How to Choose the Right Hydraulic Tube Fittings

Discover how to select the best hydraulic tube fittings for your system. Learn about hydraulic fittings names, standards, applications, and high-pressure tube fittings from Excel Flow Control.

- September 29, 2025

- By Owner

Complete Guide to PU Connectors and Fittings

Get a full overview of PU connectors and fittings. Download the PU connector size chart PDF and explore the PU fittings catalogue for reliable, cost-effective solutions from Excel Flow Control.